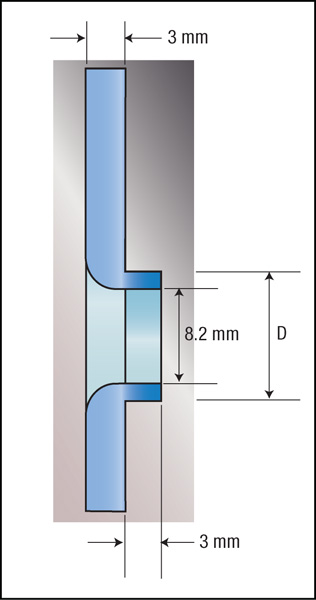

An elasto plastic incremental finite element computer code based on an updated lagrangian formulation was developed to simulate the flaring and nosing processes of a metal tube in the asisymmetric condition.

Flaring operation in sheet metal.

Instruction video for ram sheet metal unit.

Swaging is used to attach brass pins to circuit boards.

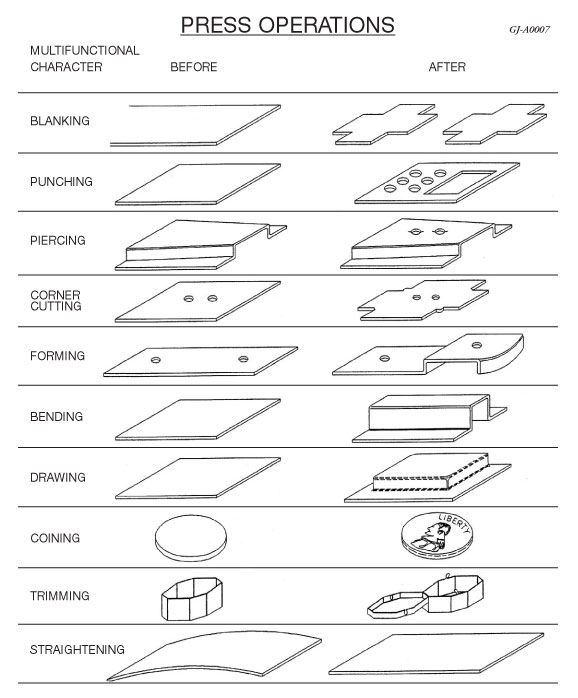

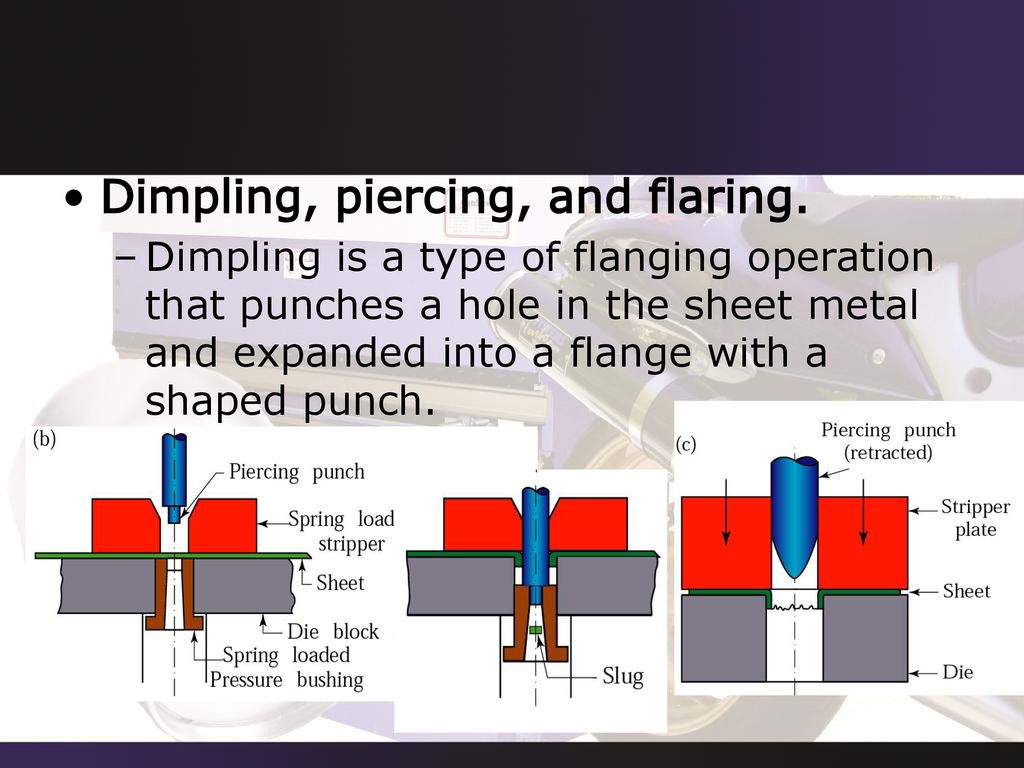

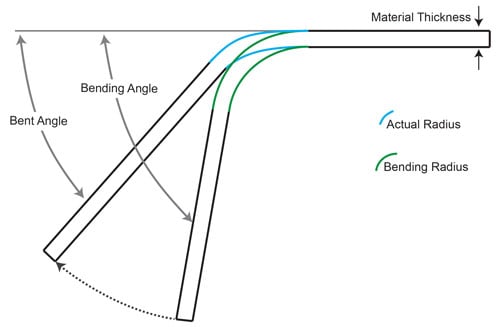

Stamping includes a variety of sheet metal forming manufacturing processes such as punching using a machine press or stamping press blanking embossing bending flanging and coining.

Stamping is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

The curled edge provides strength to the edge and makes it safe for handling.

The extended r min technique was used to treat the elastic plastic stress state and to solve contact problems at the tool metal interface.

Forming a sheet metal blank into the shape required by design is initially performed in a draw die.

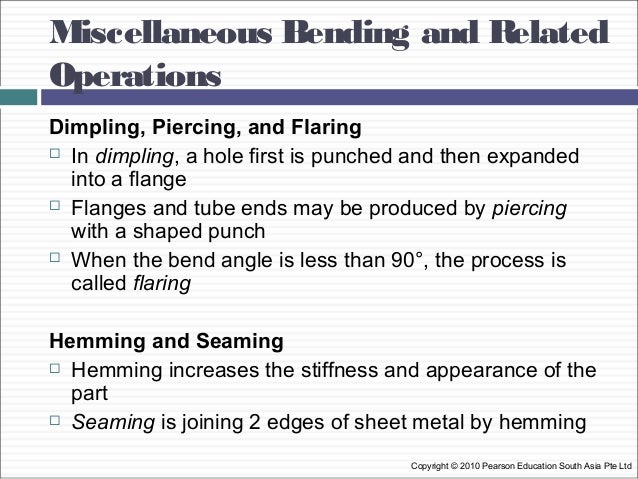

In swaging and flaring material from a post or cylinder is moved outward or inward radially to capture an edge or rim.

Flanging metal is the act of swiping sheet metal in a direction contrary to its previous position.

Grease is often used to lubricate this swaging process which is also called roller swaging.

It s also used on seat belt retractors antilock brake system cartridges and swivel joints.

Curling curling sheet metal is the process of adding a hollow circular roll to the edge of the sheet.

Instruction video for ram sheet metal unit.

The flaring is done with a pair of rolls that travel around the hole and are fed down into the part deforming the metal in a controlled predicted way.

Curling is different than a tear drop hem because in a curl the edge finishes inside itself where a hem leaves the initial edge exposed.

3d cad files are converted into machine code which controls a machine to precisely cut and form the sheets into the final part.

This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part or could occur through a.

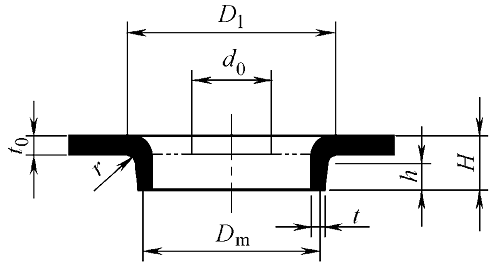

The drawing ratio is a measure of the severity of the drawing operation and is the ratio of the initial blank diameter to the punch diameter.